Specification of Manual Lathe Heavy Duty Type Lathe LS Series

* Manufacturer capability

Through technical reform, our factory purchased Japanese horizontal machining centers, British laser blade, German double column guide way grinder and other high precision, efficiency and advanced equipments. The technical level has escalated and production capacity raised. We supply first-rate products to satisfy the needs of customers both at home and abroad. Our factory is committed to bring efficient, high precision and stability to all users by insisting on providing our customers with high quality machines. We got ISO9001 certificate, CE certificate and ISO14001 certificate to ensure the best in quality. We have strong partnerships in Europe, America, South America, India, Southeast Asia and South Africa. We also supply OEM service, and we look for agents in these areas.

* Description

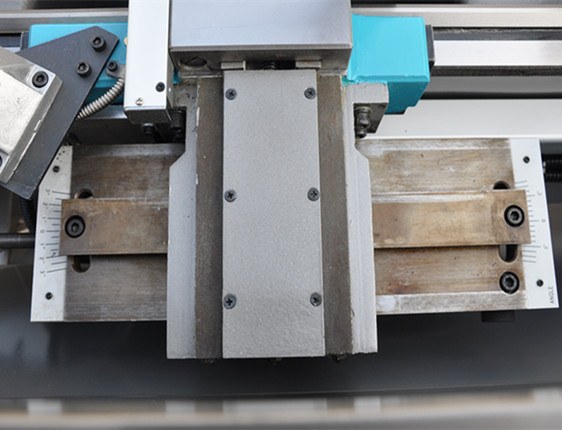

The surface of the bed ways is supersonic frequency hardened and precision ground with a long service life.

The spindle system is high in rigidity and accuracy.

Rapid feed structure is available apron.

Clutch in headstock makes the lathe start smoothly and brake quickly.

Spindle bore: Ф105mm.

Spindle speed: 5-720/5-645 rpm/min.

* Technical Specifications

| Model | LS10591×1500 | LS10591×2000 | LS10591×3000 |

| Item no. | 115084 | 115085 | 115086 |

| CAPACITY | |||

| Max.swing over bed | Ф910mm | Ф910mm | Ф910mm |

| Max.swing over carriage | Ф580mm | Ф580mm | Ф580mm |

| Max. swing over gap | Ф1100mm | Ф1100mm | Ф1100mm |

| Effective length of gap | 400mm | 400mm | 400mm |

| Width of bed | 600mm | 600mm | 600mm |

| Max.length of workpiece | 1500mm | 2000mm | 3000mm |

| Max.turning length | 1350mm | 1850mm | 2850mm |

| Max. weight of workpiece | 2000kg | 2000kg | 2000kg |

| SPINDLE | |||

| Spindle nose | D11 | D11 | D11 |

| Spindle bore | Ф105mm | Ф105mm | Ф105mm |

| Taper bore of spindle | Metric Ф120 1:20 | Metric Ф120 1:20 | Metric Ф120 1:20 |

| Steps of spindle speed | 18 | 18 | 18 |

| Range of spindle speed | 5~720rpm | 5~720rpm | 5~720rpm |

| FEED RANGE OF TOOL POST FOR PER REVOLUTION OF SPINDLE | |||

| Pitch of longitudinal ball screw/diameter | 12mm/Ф55mm | 12mm/Ф55mm | 12mm/Ф55mm |

| Number of longitudinal feeds | 64 | 64 | 64 |

| Range of longitudinal feeds (1:1) | 0.1~1.52mm/r | 0.1~1.52mm/r | 0.1~1.52mm/r |

| Range of longitudinal feeds (16:1) | 1.6~24.3mm/r | 1.6~24.3mm/r | 1.6~24.3mm/r |

| Number of cross feeds | 64 | 64 | 64 |

| Range of cross feeds | Half of longitudinal feeds | Half of longitudinal feeds | Half of longitudinal feeds |

| RAPID TRAVEL | |||

| Longitudinal | 4000mm/min | 4000mm/min | 4000mm/min |

| Cross | 2000mm/min | 2000mm/min | 2000mm/min |

| THREADING | |||

| Metric pitch threads | 1~240mm/ 50 | 1~240mm/ 50 | 1~240mm/ 50 |

| Whit-worth threads | 14~1TPI/ 26 | 14~1TPI/ 26 | 14~1TPI/ 26 |

| Module threads | 0.5~120M.P/ 53 | 0.5~120M.P/ 53 | 0.5~120M.P/ 53 |

| D.P.Threads | 28~1DP/ 24 | 28~1DP/ 24 | 28~1DP/ 24 |

| TAILSTOCK SLEEVE | |||

| Taper bore | M.T.NO.5 | M.T.NO.5 | M.T.NO.5 |

| Max.travel | 250mm | 250mm | 250mm |

| External diameter | Ф100mm | Ф100mm | Ф100mm |

| OTHERS | |||

| Vertical distance from spindle center to installing basis | 33mm | 33mm | 33mm |

| Max.travel of compound rest | 200mm | 200mm | 200mm |

| Swing angle of tool post | ±90° | ±90° | ±90° |

| Max travel of cross slide | 500mm | 500mm | 500mm |

| Size of tool shank | 32×32mm | 32×32mm | 32×32mm |

| Main motor power | 11kw | 11kw | 11kw |

| Rapid feed motor power | 1.1kw | 1.1kw | 1.1kw |

| Coolant pump power | 90w | 90w | 90w |

| Model | LS10600×1500 | LS10600×2000 | LS10600×3000 |

| Item no. | 115087 | 115088 | 115089 |

| CAPACITY | |||

| Max.swing over bed | Ф1000mm | Ф1000mm | Ф1000mm |

| Max.swing over carriage | Ф580mm | Ф580mm | Ф580mm |

| Max. swing over gap | Ф1200mm | Ф1200mm | Ф1200mm |

| Effective length of gap | 400mm | 400mm | 400mm |

| Width of bed | 600mm | 600mm | 600mm |

| Max.length of workpiece | 1500mm | 2000mm | 3000mm |

| Max.turning length | 1350mm | 1850mm | 2850mm |

| Max. weight of workpiece | 2000kg | 2000kg | 2000kg |

| SPINDLE | |||

| Spindle nose | D11 | D11 | D11 |

| Spindle bore | Ф105mm | Ф105mm | Ф105mm |

| Taper bore of spindle | Metric Ф120 1:20 | Metric Ф120 1:20 | Metric Ф120 1:20 |

| Steps of spindle speed | 18 | 18 | 18 |

| Range of spindle speed | 5~645rpm | 5~645rpm | 5~645rpm |

| FEED RANGE OF TOOL POST FOR PER REVOLUTION OF SPINDLE | |||

| Pitch of longitudinal ball screw/diameter | 12mm/Ф55mm | 12mm/Ф55mm | 12mm/Ф55mm |

| Number of longitudinal feeds | 64 | 64 | 64 |

| Range of longitudinal feeds (1:1) | 0.1~1.52mm/r | 0.1~1.52mm/r | 0.1~1.52mm/r |

| Range of longitudinal feeds (16:1) | 1.6~24.3mm/r | 1.6~24.3mm/r | 1.6~24.3mm/r |

| Number of cross feeds | 64 | 64 | 64 |

| Range of cross feeds | Half of longitudinal feeds | Half of longitudinal feeds | Half of longitudinal feeds |

| RAPID TRAVEL | |||

| Longitudinal | 4000mm/min | 4000mm/min | 4000mm/min |

| Cross | 2000mm/min | 2000mm/min | 2000mm/min |

| THREADING | |||

| Metric pitch threads | 1~240mm/ 50 | 1~240mm/ 50 | 1~240mm/ 50 |

| Whit-worth threads | 14~1TPI/ 26 | 14~1TPI/ 26 | 14~1TPI/ 26 |

| Module threads | 0.5~120M.P/ 53 | 0.5~120M.P/ 53 | 0.5~120M.P/ 53 |

| D.P.Threads | 28~1DP/ 24 | 28~1DP/ 24 | 28~1DP/ 24 |

| TAILSTOCK SLEEVE | |||

| Taper bore | M.T.NO.5 | M.T.NO.5 | M.T.NO.5 |

| Max.travel | 250mm | 250mm | 250mm |

| External diameter | Ф100mm | Ф100mm | Ф100mm |

| OTHERS | |||

| Vertical distance from spindle center to installing basis | 33mm | 33mm | 33mm |

| Max.travel of compound rest | 200mm | 200mm | 200mm |

| Swing angle of tool post | ±90° | ±90° | ±90° |

| Max travel of cross slide | 500mm | 500mm | 500mm |

| Size of tool shank | 32×32mm | 32×32mm | 32×32mm |

| Main motor power | 11kw | 11kw | 11kw |

| Rapid feed motor power | 1.1kw | 1.1kw | 1.1kw |

| Coolant pump power | 90w | 90w | 90w |

| Model | LS10610×1500 | LS10610×2000 | LS10610×3000 |

| Item no. | 115076 | 115077 | 115078 |

| CAPACITY | |||

| Max.swing over bed | Ф1100mm | Ф1100mm | Ф1100mm |

| Max.swing over carriage | Ф680mm | Ф680mm | Ф680mm |

| Max. swing over gap | Ф1300mm | Ф1300mm | Ф1300mm |

| Effective length of gap | 400mm | 400mm | 400mm |

| Width of bed | 600mm | 600mm | 600mm |

| Max.length of workpiece | 1500mm | 2000mm | 3000mm |

| Max.turning length | 1350mm | 1850mm | 2850mm |

| Max. weight of workpiece | 2000kg | 2000kg | 2000kg |

| SPINDLE | |||

| Spindle nose | D11 | D11 | D11 |

| Spindle bore | Ф105mm | Ф105mm | Ф105mm |

| Taper bore of spindle | Metric Ф120 1:20 | Metric Ф120 1:20 | Metric Ф120 1:20 |

| Steps of spindle speed | 18 | 18 | 18 |

| Range of spindle speed | 5~645rpm | 5~645rpm | 5~645rpm |

| FEED RANGE OF TOOL POST FOR PER REVOLUTION OF SPINDLE | |||

| Pitch of longitudinal ball screw/diameter | 12mm/Ф55mm | 12mm/Ф55mm | 12mm/Ф55mm |

| Number of longitudinal feeds | 64 | 64 | 64 |

| Range of longitudinal feeds (1:1) | 0.1~1.52mm/r | 0.1~1.52mm/r | 0.1~1.52mm/r |

| Range of longitudinal feeds (16:1) | 1.6~24.3mm/r | 1.6~24.3mm/r | 1.6~24.3mm/r |

| Number of cross feeds | 64 | 64 | 64 |

| Range of cross feeds | Half of longitudinal feeds | Half of longitudinal feeds | Half of longitudinal feeds |

| RAPID TRAVEL | |||

| Longitudinal | 4000mm/min | 4000mm/min | 4000mm/min |

| Cross | 2000mm/min | 2000mm/min | 2000mm/min |

| THREADING | |||

| Metric pitch threads | 1~240mm/ 50 | 1~240mm/ 50 | 1~240mm/ 50 |

| Whit-worth threads | 14~1TPI/ 26 | 14~1TPI/ 26 | 14~1TPI/ 26 |

| Module threads | 0.5~120M.P/ 53 | 0.5~120M.P/ 53 | 0.5~120M.P/ 53 |

| D.P.Threads | 28~1DP/ 24 | 28~1DP/ 24 | 28~1DP/ 24 |

| TAILSTOCK SLEEVE | |||

| Taper bore | M.T.NO.5 | M.T.NO.5 | M.T.NO.5 |

| Max.travel | 250mm | 250mm | 250mm |

| External diameter | Ф100mm | Ф100mm | Ф100mm |

| OTHERS | |||

| Vertical distance from spindle center to installing basis | 33mm | 33mm | 33mm |

| Max.travel of compound rest | 200mm | 200mm | 200mm |

| Swing angle of tool post | ±90° | ±90° | ±90° |

| Max travel of cross slide | 500mm | 500mm | 500mm |

| Size of tool shank | 32×32mm | 32×32mm | 32×32mm |

| Main motor power | 11kw | 11kw | 11kw |

| Rapid feed motor power | 1.1kw | 1.1kw | 1.1kw |

| Coolant pump power | 90w | 90w | 90w |

* Standard devices

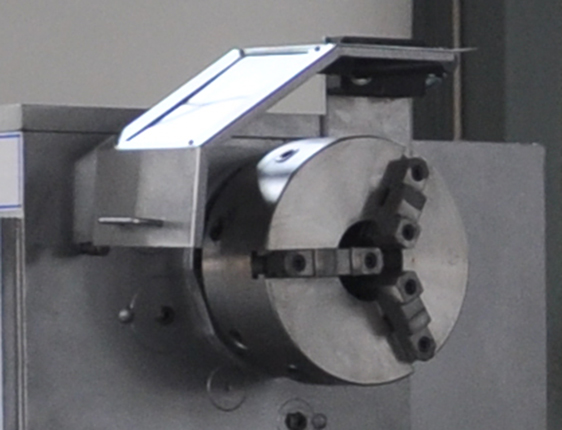

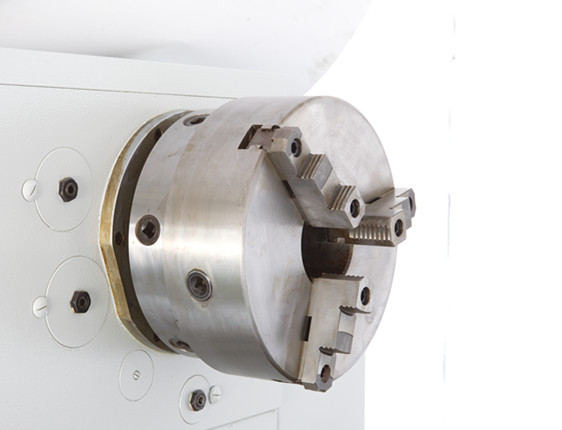

325mm 3-jaw manual chuck

500mm 4-jaw manual chuck

800mm face plate

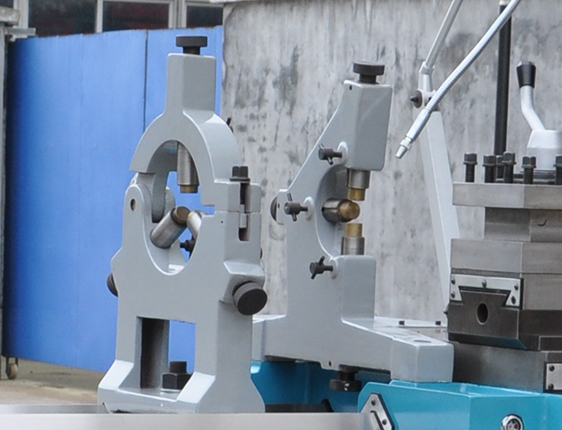

Steady rest

Follow rest

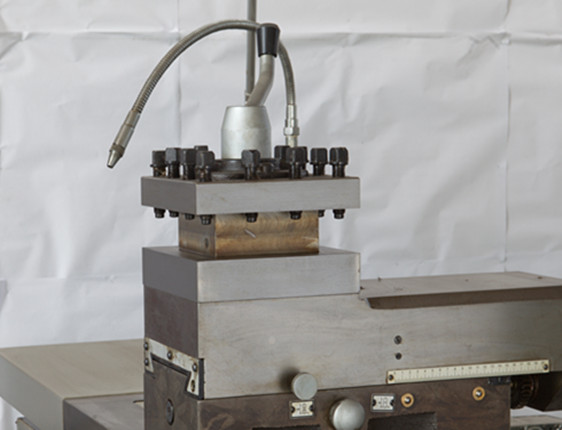

4-way tool post

Manual tailstock

Working lamp

Coolant and lubrication

* Pictures of Standard Accessories

| 4-station tool post | Manual tailstock | Face plate Ф800mm |

| Manual steady rest and follow rest | 3-jaw chuck Ф325mm and 4-jaw chuck Ф500mm |

* Ps

Max.length of workpiece also can be 4000mm,5000mm, 6000mm, 8000mm.

Payment: 30% T/T in advance, 70% T/T before shipment.

Delivery:arounds 3 months after order confirmed.

Warranty: The warranty period is general 13 months after delivery date. During the warranty period, we will provide free replacement parts (EXW) which are easy worn-out. And also parts caused by machine itself quality problems. Meanwhile, the machine should be under normal operation according to Operation Manual.(Except for improper operation or man-made damaged by buyers)

* Package